INEE Industry sp. z o.o. provides highly specialized engineering services in the field of industrial automation. As Siemens Solution Partners, our specialists provide unparalleled services, ensuring that you collaborate with the best! Reliability, constantly expanding knowledge and meticulousness - that's us!

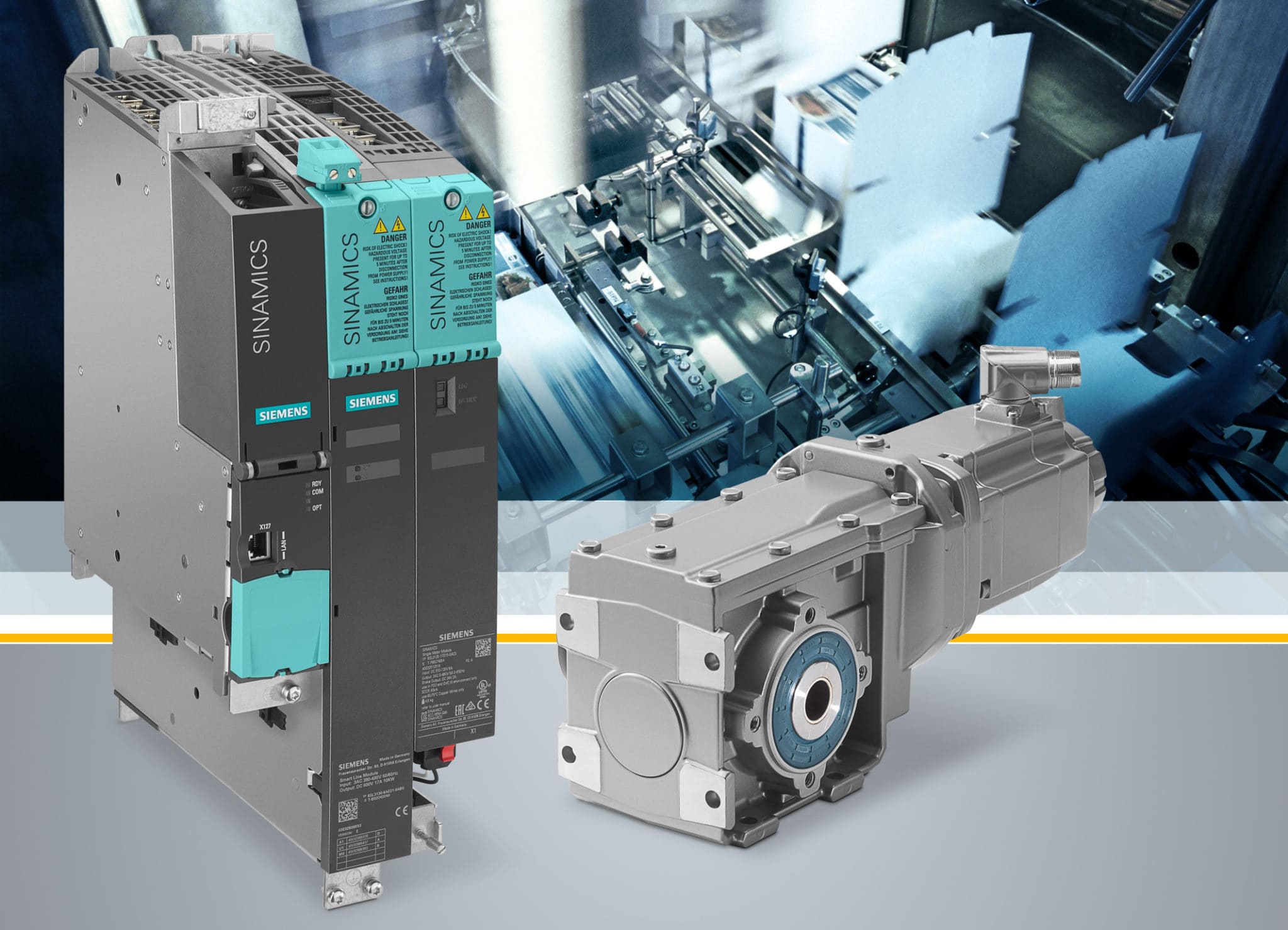

We encourage you to explore our extensive offer, including proprietary technological solutions. Combined with our knowledge and experience, these solutions enable us to undertake the most demanding projects, control systems, modernizations, or machine safety audits. Our services also encompass relocation and commissioning of production lines and machines, the implementation of vision systems, SCADA systems, as well as the programming of PLC controllers and HMI panels.

Industrial automation services

Our company provides industrial automation services such as:

- design and construction of production equipment and machinery;

- completion and implementation of robotic workstations;

- programming of PLC controllers and HMI panels;

- construction of vision product control systems;

- implementation of access control systems for machines and processes;

- integration of production management systems with the machine layer;

- automation of machinery, equipment and technological processes;

- adaptation of production lines and machines to meet legal standards and European directives;

- migrations of Siemens Simatic S5/S7 controllers and controllers from other manufacturers;

- and much more.

Who is our industrial automation offer aimed at?

Our industrial automation offer is directed to various industries. Representatives from the pharmaceutical, food, brewing, glass, automotive, woodworking, electrical, metal, and other industries primarily benefit from our project services. Every type of production that requires efficient and effective processes, focused on serial or mass production, as well as repeatability, currently utilizes industrial automation devices. These devices enable increased competitiveness in the market, ensure uninterrupted machine operation, and timely order fulfillment. We provide industrial automation solutions that are used in both technological operations and control of production processes. We also offer professional advice on optimizing production processes that involve industrial automation solutions. We warmly invite and encourage cooperation from all interested parties throughout Poland!

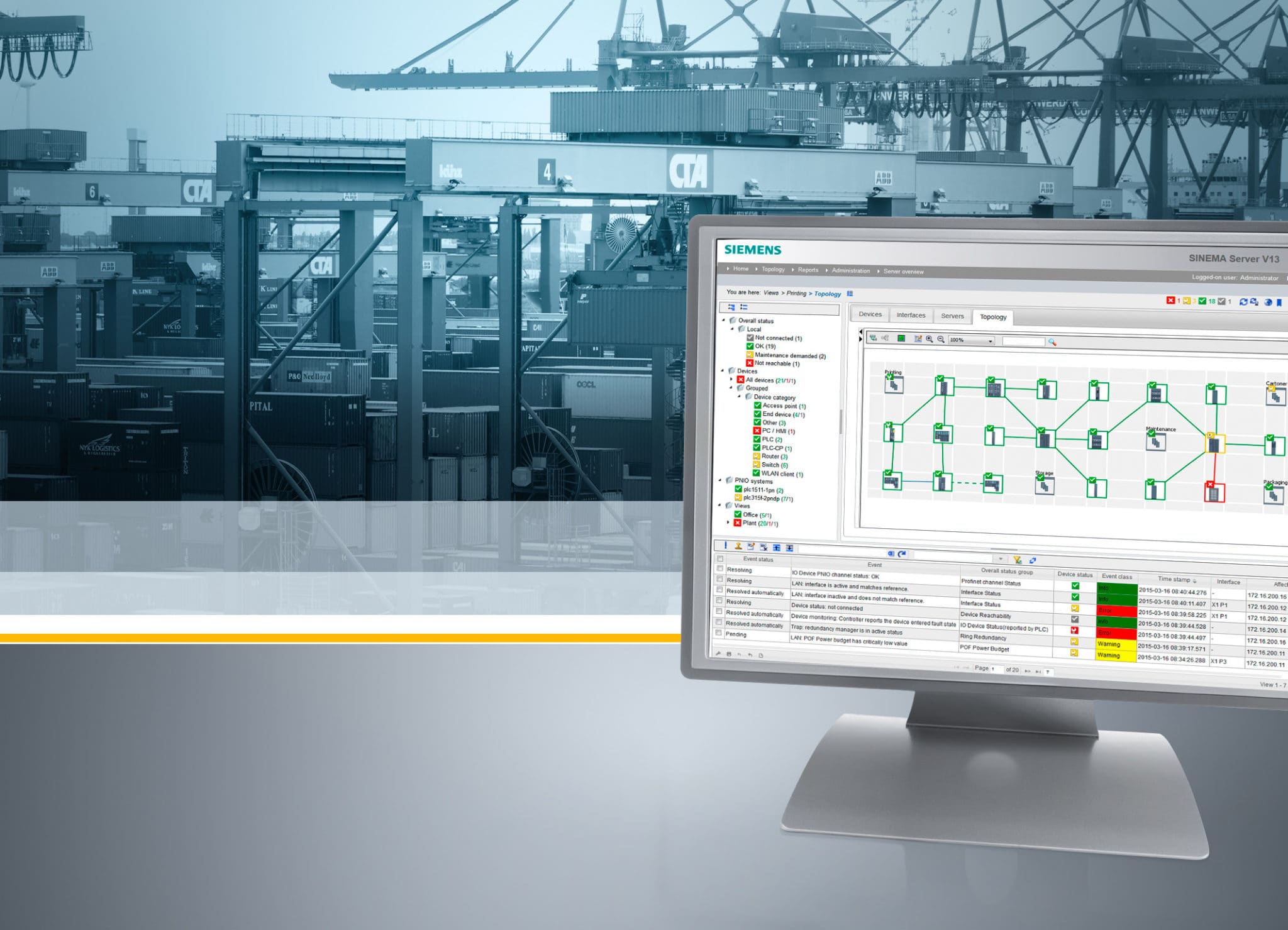

Modern industrial automation systems

Modern industrial automation systems, offered by our company, ensure consistent quality of the entire production process. Each stage of production is supervised automatically, which eliminates the risk of shortcomings or inaccuracies in the manufactured elements. Precise electronic systems control the level of operation of machines and equipment, as well as signal defects found within them and the need for maintenance of individual elements of production lines. Customers interested in raising the standard of production processes using industrial automation systems are welcome to contact us!

We provide commissioning services for production lines or machines in a new facility or after relocation

More information

Replacement of the old control based on S5 controllers with a new control system based on S7 controllers

More information

We offer ready-made systems dedicated to cooperation with available machines, or other dedicated services

More information